Ningbo Lituo Superfine Materials Co., LTD.

News center

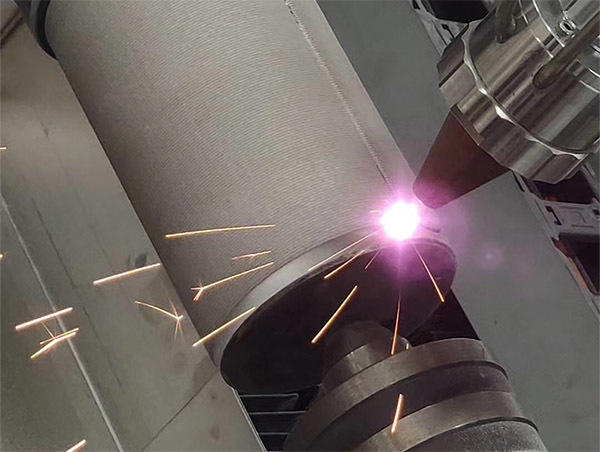

Detailed technical introduction and characteristics of laser cladding metal surface repair

30 May,2024

The repair technology of laser cladding manufacturers is to use high-power laser light, which is controlled by the laser cutting processing system software under the control of the CNC machine tool to produce a too thin micro-melting layer at a specific position on the conventional surface layer. In addition, a preset or simultaneous method is used. With special composition of self-fluxing alloy powders, such as nickel-based, cobalt-based and iron-based alloys, they can be spread symmetrically on the surface of the part in a molten state and achieve a predetermined thickness. It produces excellent metallurgy with micro-melting conventional metal composite materials. Industrial integration, and there is only a small degree of dilution between each other. In the whole process of subsequent rapid condensation, the surface layer of the part is completely different from the conventional one. It has the function of cladding the raw material layer with the unique characteristics of the reservation, and then can completely Changing the characteristics of the surface layer of the raw material can make the surface layer of the high-quality and low-cost raw material obtain high wear resistance, corrosion resistance, and heat resistance.The processing technology can repair the holes and cracks on the surface of the raw material, and can repair the geometrical specifications and characteristics of the damaged parts.