Ningbo Lituo Superfine Materials Co., LTD.

Cutting-edge ultrafine metal powder making equipment

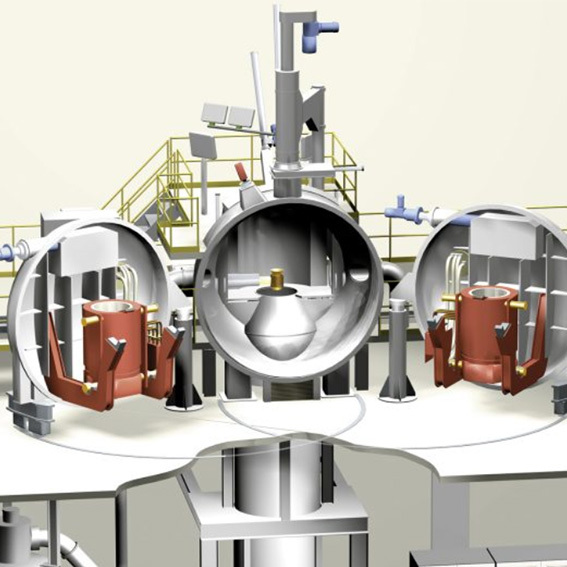

Vacuum melting gas atomization powder making experimental grade equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

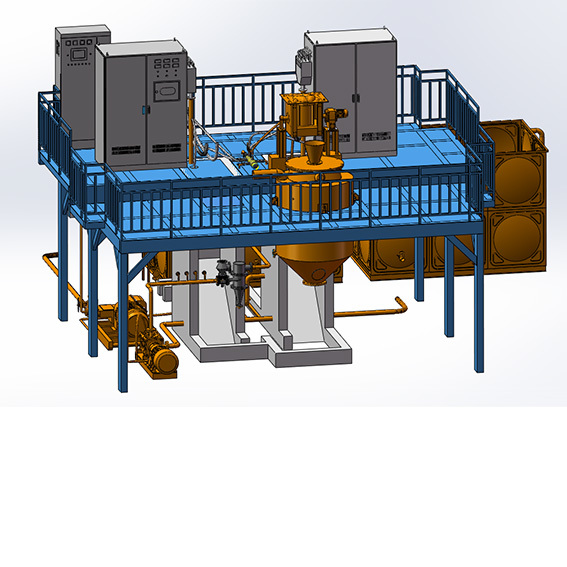

Vacuum melting gas atomization powder making equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

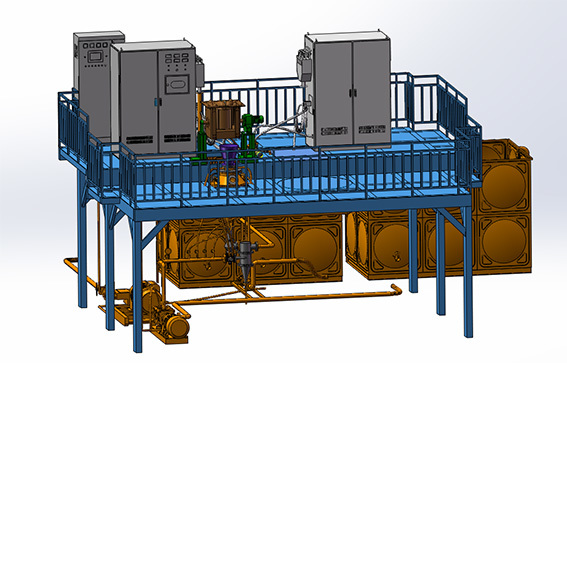

Vacuum Suspension Melting Aerosolized Powder Making Experimental Grade Equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Vacuum suspension melting gas atomization powder making equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Air-jet water-cooled atomized powder making equipment

Air-jet water-cooled atomized powder making equipment is a modern powder making equipment that works under atmospheric atmospheric pressure and uses the principle of medium-frequency induction to melt metal materials, and the molten liquid is aerosolized and quickly solidified through the infusion nozzle that is dumped to the lower part of the intermediate package.

High-pressure water atomization powder making equipment

High-pressure water atomization powder making equipment is a modern powder making equipment that works under atmospheric atmospheric pressure and uses the principle of medium-frequency induction to melt metal materials, and the molten liquid is atomized by high-pressure water through the infusion nozzle dumped to the lower part of the intermediate packet and solidified quickly.

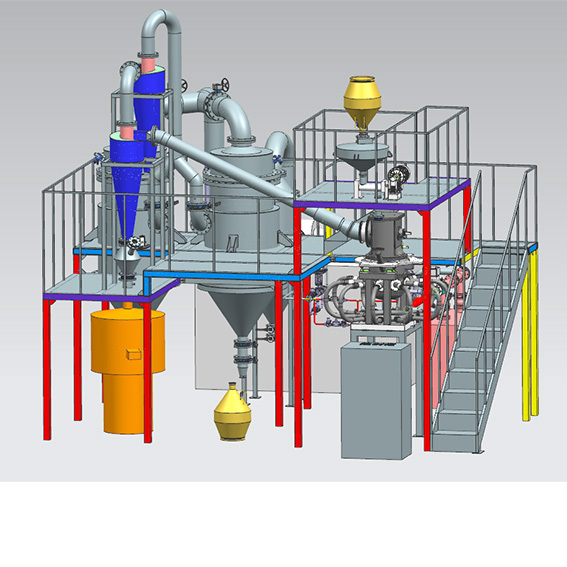

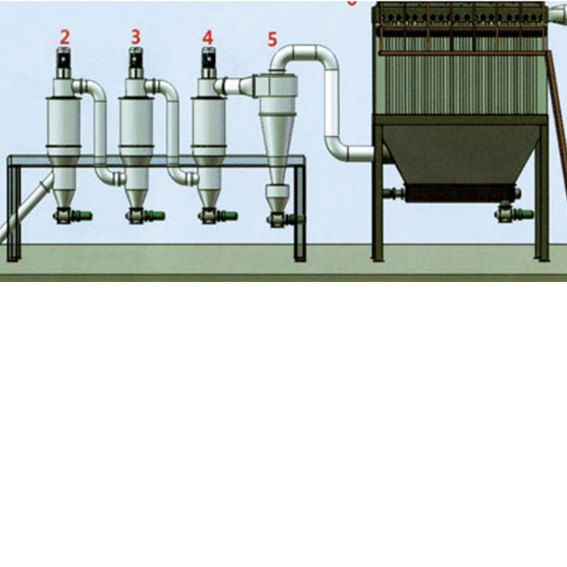

Air flow ultra-micro pulverizer series equipment

The basic composition of the gas mill production line includes: gas compressor, gas tank, gas dryer, air purification filters, gas mill, cyclone separator, bag duster and induced draft fan and so on. One of the airflow mill by the spiral gas pedal, crushing chamber, grading room and other components, the use of low-temperature, high-pressure gas through a special device of supersonic nozzle generated by the high-speed airflow contains a huge kinetic energy, so that the material with the gas acceleration impact on each other to achieve the purpose of crushing.

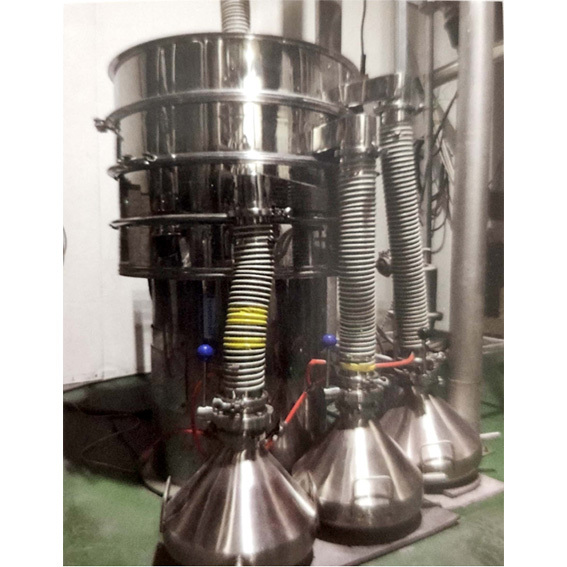

Vibrating screen is a screening equipment integrating debris removal, grading and filtration, which is mainly used to deal with powder, granule and liquid materials, and adopts vertical vibration motor as the excitation source, and the material makes horizontal, vertical and inclined three-dimensional movement on the screen surface, with high screening precision. Rotary vibration sieve material can be divided into carbon steel, stainless steel, plastic three kinds of materials, in addition, the rotary vibration sieve can also be selected according to the purpose of screening 1~5 layers of screen mesh design, according to the requirements of the screening process, the rotary vibration sieve can be used in the direct drain type, plus the edge of the type, the gate type and other designs, to meet the screening requirements of more industries.

Combining the configuration of conventional high-pressure gas station and the aerosolization powder making process in the atomization process with a large gas flow, atomization gas cycle has a stable time interval characteristics, the company developed for the special aerosolization powder making equipment for the instantaneous high-flow high-pressure gas station.

Raw materials are fed into the crushing chamber by quantitative feeding, the materials are scattered to the periphery of the crushing disk under the action of centrifugal force, and crushed and depolymerized by the high-speed impact of the hammer head, shear, grinding, and crushing, the materials are crushed by the induced draft fan under negative pressure pumped into the vertical classifier, coarse particles are sorted by the classifier to fall back into the regrind, and the fines are with the negative airflow into the cyclone collector or the cloth bag collector to collect the separation of air and solid, and the materials are discharged from the discharge valve that is, finished products, the air is cleaned by the dust catcher through the fan and muffler, then discharged into the air. The material is discharged from the unloading valve as the finished product, and the air is purified by the dust collector and discharged through the fan and muffler.