Ningbo Lituo Superfine Materials Co., LTD.

News center

13 May,2024

In order to further standardize the company’s production, scientific research, and sales operation procedures, effectively control risks, increase investment returns, and form a standardized operation and standardized management model, the company started from a strategic perspective, carried out the introduction of the ISO9001 quality management system, and successfully passed the ISO9001 quality management System certification, obtained the ISO9001 quality management system certification on July 2, 2020.

13 May,2024

Warmly celebrate the company's "new year of relocation"

Ningbo Zhongwu Rio Tinto ultramicro Material Co., Ltd. is a high-tech enterprise specializing in the R & D, production and sales of complete sets of metal atomization pulverizing equipment, all kinds of ultramicro metal powder, high-speed laser cladding equipment and supersonic spraying equipment. We will forge ahead and keep pace with the times; Continuous innovation.

13 May,2024

Tigers are strong, build dreams and move forward

Time always passes silently, and we need a little sense of ritual to bid farewell to the past and welcome a new year.

16 Sep,2025

Exploring the Innovations of Ningbo Lituo Superfine Materials Co.

Discover the latest updates and innovations from Ningbo Lituo Superfine Materials Co., a leader in advanced materials.

15 Sep,2025

Unlocking the Secrets of Fine Powder: News You Can't Miss!

Dive into the fascinating world of fine powder, exploring its uses, benefits, and the latest news surrounding this versatile substance.

14 Sep,2025

The Latest Buzz: How Equipment Is Shaping the Future of News

Discover how cutting-edge equipment is revolutionizing news reporting and broadcasting.

13 Sep,2025

The Buzz Around LTD: Your Go-To for News Insights

Explore the latest trends and insights fromLimited Stay updated with engaging news content!

12 Sep,2025

Revolutionizing Industries with Cutting-Edge Ultrafine Metal Powder Making Equipment

Discover how cutting-edge ultrafine metal powder making equipment is transforming industries with innovative technology.

30 May,2024

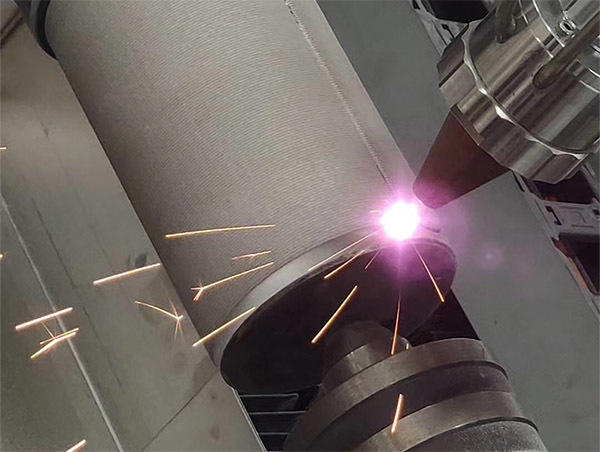

Detailed technical introduction and characteristics of laser cladding metal surface repair

The repair technology of laser cladding manufacturers is to use high-power laser light, which is controlled by the laser cutting processing system software under the control of the CNC machine tool to produce a too thin micro-melting layer at a specific position on the conventional surface layer. In addition, a preset or simultaneous method is used. With special composition of self-fluxing alloy powders, such as nickel-based, cobalt-based and iron-based alloys, they can be spread symmetrically on the surface of the part in a molten state and achieve a predetermined thickness. It produces excellent metallurgy with micro-melting conventional metal composite materials. Industrial integration, and there is only a small degree of dilution between each other. In the whole process of subsequent rapid condensation, the surface layer of the part is completely different from the conventional one. It has the function of cladding the raw material layer with the unique characteristics of the reservation, and then can completely Changing the characteristics of the surface layer of the raw material can make the surface layer of the high-quality and low-cost raw material obtain high wear resistance, corrosion resistance, and heat resistance.The processing technology can repair the holes and cracks on the surface of the raw material, and can repair the geometrical specifications and characteristics of the damaged parts.

30 May,2024

What are the characteristics of side-axis powder feeding laser cladding technology?

Side-axis powder feeding laser cladding technology is also called lateral powder feeding laser cladding technology, which generally uses semiconductor direct output lasers or semiconductor fiber output lasers and gravity feeders, and the cladding head uses a rectangular spot +Aside shaft broadband powder feeding program. When the laser cladding manufacturer is working on the cladding head, the alloy powder is transported to the surface of the workpiece through the powder feeding nozzle for preset. With the relative movement of the cladding head and the workpiece, the rectangular laser beam scans the preset alloy powder and It melts to form a molten pool, and forms a cladding layer after cooling. Laser cladding manufacturers here are some specific features of side-axis powder feeding laser cladding technology, hoping to help you: