Ningbo Lituo Superfine Materials Co., LTD.

News center

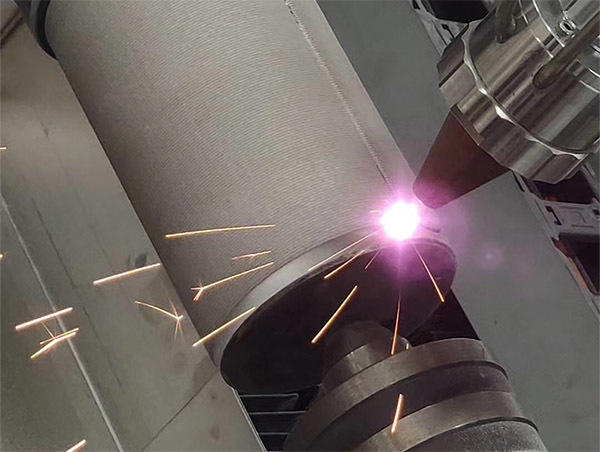

Revolutionizing Industries with Cutting-Edge Ultrafine Metal Powder Making Equipment

12 Sep,2025

The Future of Metal Powder Production

In the ever-evolving world of manufacturing, the quest for precision and efficiency is relentless. Enter the realm of cutting-edge ultrafine metal powder making equipment, a game-changer that's reshaping how industries operate. With applications ranging from aerospace to electronics, this technology is not just about making metal powders; it's about redefining possibilities!

What Are Ultrafine Metal Powders?

So, what's the big deal with ultrafine metal powders? Well, these tiny particles, often less than 100 micrometers in size, boast incredible surface area to volume ratios. This characteristic allows them to exhibit unique properties, making them ideal for various applications. Think about it: in sectors where precision is paramount, ultrafine powders are the secret sauce that enhances performance!

Why Go Ultrathin?

Let's face it; the manufacturing landscape is brutal. To stay ahead of the curve, companies need to adopt innovative technologies. That's where ultrafine metal powder making equipment comes into play! The benefits are enormous:

- Enhanced Performance: Ultrafine powders lead to superior mechanical properties and greater strength.

- Improved Efficiency: Processes become more efficient, reducing waste and saving time.

- Versatility: These powders can be used in 3D printing, welding, and even in the production of batteries!

The Magic of Cutting-Edge Technology

Now, let's get into the nitty-gritty of what makes this equipment cutting-edge. With advanced features like real-time monitoring and automated production lines, manufacturers can produce ultrafine metal powders with pinpoint accuracy. This means less guesswork and more focus on what really matters: quality.

Applications Galore!

From automotive to biomedical fields, the applications of ultrafine metal powders are as varied as they are exciting. For instance:

- Aerospace: Lightweight and strong materials are crucial for aircraft and spacecraft design.

- Electronics: In the world of electronics, ultrafine powders are vital for making conductive pastes and inks.

- Medical Devices: Precision in medical equipment is non-negotiable, and ultrafine powders help achieve that.

The Environmental Angle

But wait, there's more! The adoption of ultrafine metal powder making equipment also contributes to sustainability. As industries strive for greener practices, these processes often utilize less material and energy than traditional methods. It's a win-win for both manufacturers and Mother Earth!

Challenges on the Horizon

Of course, no technology comes without its hurdles. The initial investment for cutting-edge ultrafine metal powder making equipment can be steep. Plus, mastering the technology requires a skilled workforce. But hey, where there's a will, there's a way, right?

The Bottom Line

As we look to the future, it's clear that cutting-edge ultrafine metal powder making equipment is not just a passing trend; it's a revolution. With its ability to enhance performance, improve efficiency, and contribute to sustainability, it's a technology that's here to stay. Are you ready to embrace the change?