Ningbo Lituo Superfine Materials Co., LTD.

News center

Laser cladding manufacturers: an overview of the application status of laser cladding in heating diesel engines

30 May,2024

Laser cladding manufacturer. As a key transmission equipment indispensable for people, the heating diesel engine plays a key role in power engineering, electric energy transportation, national defense, airlines, ocean navigation, ships, rails and other land driving forces. Common heating diesel engines include gas turbines, gas turbines and steam power systems.

Laser cladding equipment. It can be said that the reason for the ineffectiveness of the gas turbine comes from the heat consumption, but in the end, the common faults of the gas turbine are caused by the comprehensive effect of various influencing factors, such as mechanical equipment load, erosion and friction damage. The key failure modes include rupture and cracking of internal metal material components, severe damage or erosion, and partial fall off. Laser cladding.

Laser cladding manufacturer. The key metal material parts mentioned in the original text include cylinder liners, piston rods, engine pistons, camshaft tappets, engine crankshafts, etc. This kind of parts bears the tempering of natural gas ultra-high pressure on a different level. It bears the effect of corrosive substances for a long time, and the effect of mechanical equipment ground stress caused by volume load, and it can be found that most of the damage occurs on the surface. Or starting from the surface, improving the surface characteristics of the parts has a key effect on increasing the service life of the parts. In addition, the surface damage locations that have undergone regular maintenance and timely treatment can also be rescued according to the surface reproduction technology. Laser cladding.

Laser cladding manufacturer. For gas turbines and steam turbines, invalid positions often occur on hot-end components, such as motor rotors, leaves and nozzles. The invalidity of this position is due to different software environments, which can be summarized as thermal fatigue and external corrosion. Wait. The rupture at the root of the leaf cannot be repaired, and the damage at the top or root of the leaf can be used after repair. Secondly, the leaves used for diesel generators usually have a very high engineering cost. Reinstalling and reusing the repaired leaves will greatly reduce the cost of power generation. Laser cladding equipment.

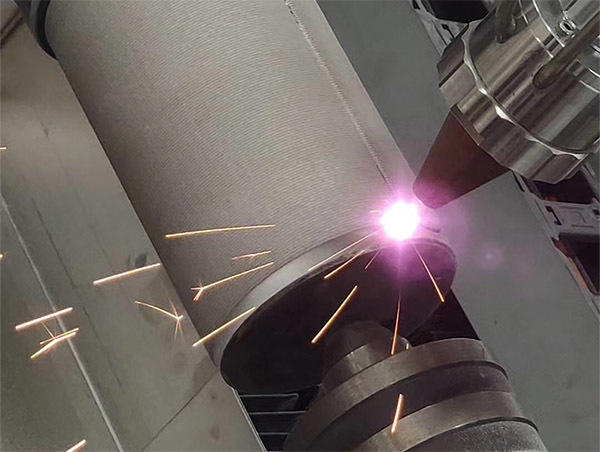

Laser cladding. Whether it is the strengthening of the surface layer of the part before active service or the repair of common faults after active service, the traditional production and processing methods are induction hardening, surface nitriding or high frequency quenching, thermal spraying, spray welding, etc. Thermal spraying and spray welding are more widely used in middle and late repairs. With the continuous upgrading and improvement of production and processing technology, a milestone practical production and processing technology has quickly become a brand new technology introduced by various manufacturers in the processing and manufacturing industry, that is, laser mobile reproduction technology. Laser cladding equipment.