Ningbo Lituo Superfine Materials Co., LTD.

News center

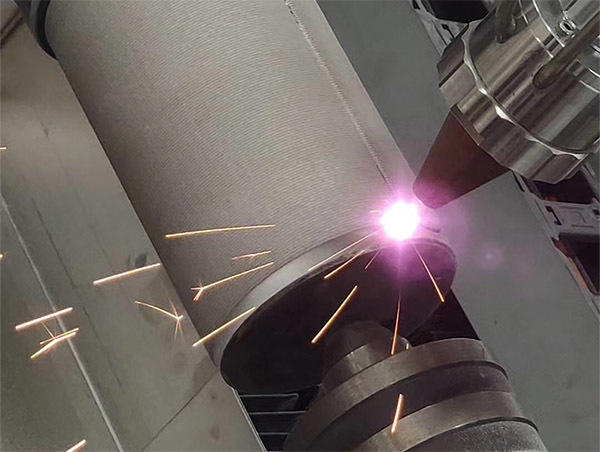

What are the application areas of laser cladding technology?

30 May,2024

Laser cladding processing technology has a wide range of applications and applications, covering almost the entire machinery manufacturing industry,therefore, laser cladding technology has greatly promoted the rapid development of the national economy, and this phenomenon has greatly stimulated the development of laser cladding manufacturers. After the continuous progress of laser cladding manufacturers, laser cladding technology is currently widely usedStainless steel, die steel, malleable cast iron, gray cast iron, copper alloy, titanium alloy, aluminum alloy and special alloy surface cobalt-based, nickel-based, iron-based and other self-fluxing alloy powders and ceramicsand other fieldslaser cladding。

Manufacturing and remanufacturing of mining equipment and its partsdomain pair laser cladding technologyapplications

The equipment of coal mining machinery is used in large quantities and wears quickly. Due to the harsh working environment, the parts and components are damaged relatively quickly.Laser cladding manufacturers have also seen the areas of continuous improvement in the development of this industry. The various types of parts and components of coal mining equipment manufactured and remanufactured using laser cladding technology mainly include:shearer`smain frame, rocker arms, gears, gear shafts, various bushes, articulated frames, cylinders, cylinder seats, guide shoes, sprocket wheels, pin rail wheels, drive wheels, picks;roadheader`sCylinders, brackets, shafts, various bushes, picks, etc.

Application of Laser Cladding Technology in the Manufacturing and Remanufacturing of Power Equipment and Parts

Power equipment is distributed in a large amount and runs uninterruptedly, and its parts have a high probability of damage. Steam turbine is the core equipment of thermal power generation. Due to the special working conditions of high temperature and high heat, it is necessary to regularly repair damaged unit parts, such as main shaft diameter and moving blades, every year. Gas turbines are often damaged due to their working under high temperature conditions as high as 1300℃1300℃laser cladding manufacturersAlways think,Using laser claddingtechnologyAll its defects are repaired intact and its performance is restored. The cost is only the price of the new unit1/10, can greatly reduce maintenance costs.