Ningbo Lituo Superfine Materials Co., LTD.

News center

What are the characteristics of side-axis powder feeding laser cladding technology?

30 May,2024

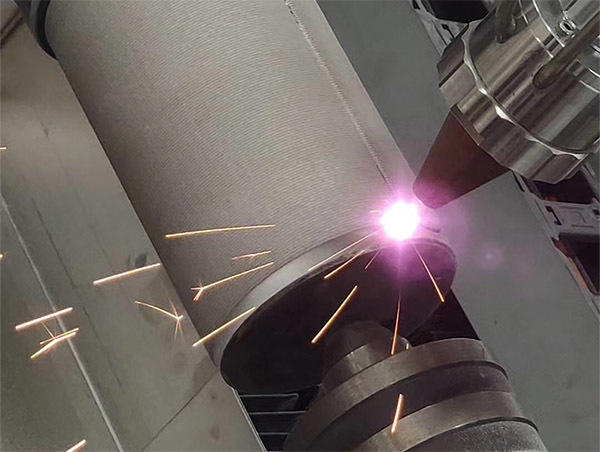

Side-axis powder feeding laser cladding technology is also called lateral powder feeding laser cladding technology, which generally uses semiconductor direct output lasers or semiconductor fiber output lasers and gravity feeders, and the cladding head uses a rectangular spot +Aside shaft broadband powder feeding program. When the laser cladding manufacturer is working on the cladding head, the alloy powder is transported to the surface of the workpiece through the powder feeding nozzle for preset. With the relative movement of the cladding head and the workpiece, the rectangular laser beam scans the preset alloy powder and It melts to form a molten pool, and forms a cladding layer after cooling. Laser cladding manufacturers here are some specific features of side-axis powder feeding laser cladding technology, hoping to help you:

Side shaft powder feeding laser cladding technology features high material utilization

Compared with coaxial powder feeding, the material utilization rate of the laser cladding technology with side-axis powder feeding can reach more than 95%. Coaxial powder feeding laser cladding technology powder is blown into the laser molten pool by inert gas. In this process, due to the collision between the powders, the splash of the molten pool and the accuracy of the powder feeding channel, A considerable proportion of metal powder cannot form a cladding layer and is wasted, resulting in a material utilization rate of only about 50%-80% (the smaller the light spot, the lower the material utilization rate). In the side-axis powder feeding laser cladding, the powder is preset on the surface of the workpiece, and the laser beam is scanned and irradiated to melt it, which can achieve a very high material utilization rate and save more material costs.

Side shaft powder feeding laser cladding technology features high cladding efficiency

Because the side-axis powder feeding laser cladding technology adopts the rectangular spot scheme, while ensuring the energy density of the spot in the cladding direction, the laser power and spot width can be increased, which greatly improves the cladding efficiency. At present, the width of single-pass cladding in actual production can reach more than 30mm, and the cladding efficiency can reach 1m²/h or 12Kg/h.

Due to its high efficiency and low cost, side-axis powder feeding laser cladding technology is generally used for surface cladding and additive remanufacturing of parts with large areas and simple shapes such as hydraulic cylinders and rolls.