Ningbo Lituo Superfine Materials Co., LTD.

Classification:

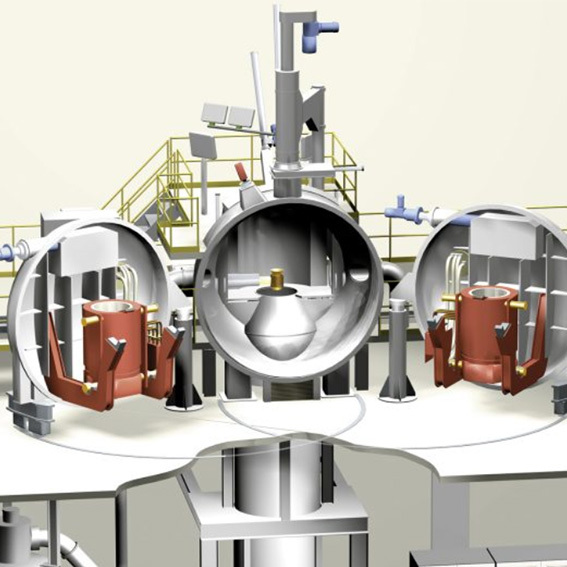

Double-action mixer

Double power mixer is a new type, high efficiency, fine container rotary blade mixer, with a variety of powdered, granular materials mixed evenly, with a high degree of uniformity of mixing, the specific gravity of the difference between large, small amount of ingredients can also achieve a better mixing degree.

INQUIRY

Product Description:

Double power mixer is a new type, high efficiency, fine container rotary blade mixer, with a variety of powdery, granular materials mixed evenly, with a high degree of uniformity of mixing, the specific gravity of the difference between the ingredients, add a small amount of the same can achieve a good degree of mixing. Barrel volume 50L-5000L, according to customer requirements for customized production.

Principle of operation.

Barrel 360 ° turning movement, with three-dimensional movement, so that the material from the agglomeration to the dispersed state and mixed with each other, mixing without dead ends, to achieve full convection of the material, diffusion mixing to ensure that the material is mixed uniformly; the internal full-size mixing blades to force shear, stirring the material to accelerate the flow of the material diffusion effect of the material to achieve the material in the barrel of the irregular, very complex movement to achieve the shear mixing of powders, thus enabling the material to be fully mixed uniformly and with high efficiency. The material can be fully mixed evenly and with high efficiency.

Features of the double-action mixer:

1. Combining the traditional mixer's space inversion and forced stirring mixing process in one, mixing efficiency is higher.

2. Single motor has only one moving part, high durability and easy maintenance.

3. Double frequency conversion speed control for barrel and blade, according to different material characteristics, adjust the speed to achieve better mixing effect.

4. Double timer, record the total mixing time and blade forward and reverse cycle time.

5. Positive and negative pointing function, at the end of mixing, you can adjust the barrel orientation by positive and negative pointing function.

6. The loading capacity is up to 85%, twice as much as the traditional mixer.

Keyword:

Magnesium-based hydrogen storage materials

Cutting-edge ultrafine metal powder making equipment

Customized powder varieties can be customized for customers

Related Products

Vacuum melting gas atomization powder making experimental grade equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum melting gas atomization powder making equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum Suspension Melting Aerosolized Powder Making Experimental Grade Equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Vacuum suspension melting gas atomization powder making equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Just in touch us

Address

No.346 Ninghe Road, Yinzhou District, Ningbo City, Zhejiang Province

Tel

Technical consulting

86-13980131787(Mr.liu)

86-13736014811(Miss Liu)