Ningbo Lituo Superfine Materials Co., LTD.

Classification:

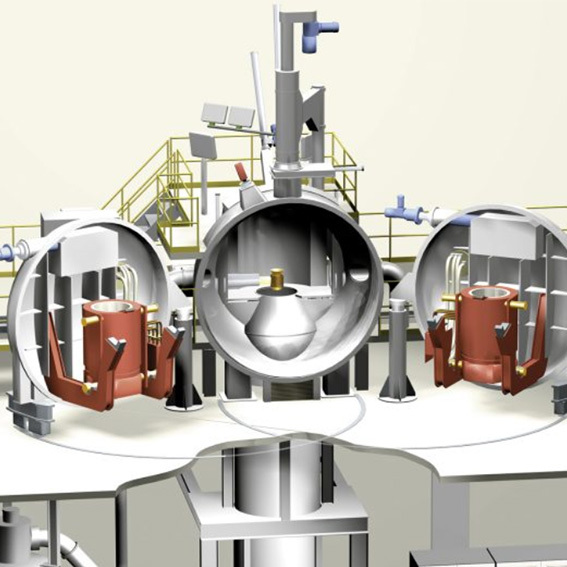

Vacuum suspension melting gas atomization powder making equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

INQUIRY

Principles and Uses:

Vacuum suspension melting gas atomization powder making equipment melts the metal material under vacuum condition (or inert gas filling) by using the principle of medium-frequency induction heating, and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using the magnetic squeezing and stirring effect, which is in the suspension state, and it avoids the contamination of the crucible to the metal liquid. After completing the melting, the metal liquid flows out through the guide nozzle at the bottom of the crucible, which is atomized by the high-pressure gas and solidified into powder quickly, which can control the alloy composition better. It can make pure titanium, multi-species titanium alloy, high entropy alloy, chromium, high purity refractory alloy powder;

Features:1.Copper cold wall suspension melting can avoid the pollution of crucible to metal liquid.

2. The first international ultrasonic two-phase flow laminar flow aerosolization powder making technology, with short atomization time, high powder yield and greatly reduced production cost (Patent No.: ZL201010291650.8).

3. The powder obtained by atomization has high sphericality, low oxygen increment and controllable particle size distribution.

4. The chemical composition of the atomized powder has no segregation, uniform organization and fine grain size.

5. Different alloy powder oxygen content and particle size can be optimized by adjusting process parameters.

6. A variety of metals and their alloy powders that can not be manufactured by water atomization methods and atmospheric conditions can be produced.

7. The atomized high-pressure gas is in the state of ultra-high speed of sound, ultrasonic gas-liquid two-phase flow, which can rapidly reduce the temperature of the powder, so that the powder has a better spherical degree.

8. When atomizing powder, there are fewer unalloyed elements, high purity, good repeatability of the alloy powder produced, and adaptable to mass production.

9. According to the principle of aerodynamics, flow field distribution mathematical model, with the spray disk aerodynamic flow field computer simulation design of the atomization powder system, equipped with satellite ball removal device, can effectively avoid or reduce the satellite ball and the generation of hollow powder.

10. The equipment is equipped with automatic opening and closing system for the melting chamber door and the conical hopper of atomization bin.

11. According to the customer's demand, it can be equipped with automatic cleaning device of atomization bin, which greatly shortens the cleaning time of atomization bin (Patent No.: 201920106743.5).

12. One powder making equipment can be configured with three kinds of crucible melting capacity, which is suitable for mass production and powder trial production.

Keyword:

Magnesium-based hydrogen storage materials

Cutting-edge ultrafine metal powder making equipment

Customized powder varieties can be customized for customers

Related Products

Vacuum melting gas atomization powder making experimental grade equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum melting gas atomization powder making equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum Suspension Melting Aerosolized Powder Making Experimental Grade Equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Vacuum suspension melting gas atomization powder making equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Just in touch us

Address

No.346 Ninghe Road, Yinzhou District, Ningbo City, Zhejiang Province

Tel

Technical consulting

86-13980131787(Mr.liu)

86-13736014811(Miss Liu)