Ningbo Lituo Superfine Materials Co., LTD.

Classification:

depolymerizer

Raw materials are fed into the crushing chamber by quantitative feeding, the materials are scattered to the periphery of the crushing disk under the action of centrifugal force, and crushed and depolymerized by the high-speed impact of the hammer head, shear, grinding, and crushing, the materials are crushed by the induced draft fan under negative pressure pumped into the vertical classifier, coarse particles are sorted by the classifier to fall back into the regrind, and the fines are with the negative airflow into the cyclone collector or the cloth bag collector to collect the separation of air and solid, and the materials are discharged from the discharge valve that is, finished products, the air is cleaned by the dust catcher through the fan and muffler, then discharged into the air. The material is discharged from the unloading valve as the finished product, and the air is purified by the dust collector and discharged through the fan and muffler.

INQUIRY

Principle of operation.

Raw materials are fed into the crushing chamber by quantitative feeding, the materials are scattered to the periphery of the crushing disk under the action of centrifugal force, and crushed and depolymerized by the high-speed impact of the hammer head, shear, grinding, and crushing, the materials are crushed by the induced draft fan under negative pressure pumped into the vertical classifier, coarse particles are sorted by the classifier to fall back into the regrind, and the fines are with the negative airflow into the cyclone collector or the cloth bag collector to collect the separation of air and solid, and the materials are discharged from the discharge valve that is, finished products, the air is cleaned by the dust catcher through the fan and muffler, then discharged into the air. The material is discharged from the unloading valve as the finished product, and the air is purified by the dust collector and discharged through the fan and muffler.

Characteristics of the depolymerizer:

1. Vertical ultra-micro impact mill, traditional pulverizer, wide feeding range, crushing precision, suitable for a variety of things, widely used in various industries, suitable for a wide range of materials within 6 Mohs hardness.

2. With crushing, depolymerization, dispersing, shaping and other functions, at the same time can do pickaxe aluminum protection and spray protection and other protective facilities, applied to high-purity industry, and can do closed-circuit recycling system.

Keyword:

Magnesium-based hydrogen storage materials

Cutting-edge ultrafine metal powder making equipment

Customized powder varieties can be customized for customers

Related Products

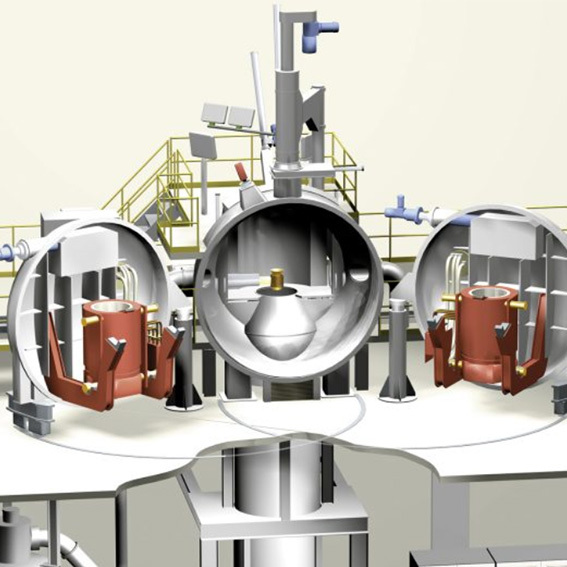

Vacuum melting gas atomization powder making experimental grade equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum melting gas atomization powder making equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum Suspension Melting Aerosolized Powder Making Experimental Grade Equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Vacuum suspension melting gas atomization powder making equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Just in touch us

Address

No.346 Ninghe Road, Yinzhou District, Ningbo City, Zhejiang Province

Tel

Technical consulting

86-13980131787(Mr.liu)

86-13736014811(Miss Liu)