Ningbo Lituo Superfine Materials Co., LTD.

Classification:

vibrating screens

Vibrating screen is a screening equipment integrating debris removal, grading and filtration, which is mainly used to deal with powder, granule and liquid materials, and adopts vertical vibration motor as the excitation source, and the material makes horizontal, vertical and inclined three-dimensional movement on the screen surface, with high screening precision. Rotary vibration sieve material can be divided into carbon steel, stainless steel, plastic three kinds of materials, in addition, the rotary vibration sieve can also be selected according to the purpose of screening 1~5 layers of screen mesh design, according to the requirements of the screening process, the rotary vibration sieve can be used in the direct drain type, plus the edge of the type, the gate type and other designs, to meet the screening requirements of more industries.

INQUIRY

Products

Vibrating screen is a screening equipment integrating debris removal, grading and filtration, which is mainly used to deal with powder, granule and liquid materials, and adopts vertical vibration motor as the excitation source, and the material makes horizontal, vertical and inclined three-dimensional movement on the screen surface, with high screening precision. Rotary vibration sieve material can be divided into carbon steel, stainless steel, plastic three kinds of materials, in addition, the rotary vibration sieve can also be selected according to the purpose of screening 1~5 layers of screen mesh design, according to the requirements of the screening process, the rotary vibration sieve can be used in the direct drain type, plus the edge of the type, the gate type and other designs, to meet the screening requirements of more industries.

Three main features:

1. Classification: It can accurately classify powder and granule into 2-5 grades, and the precision of classification can be more than 95%.

2. Removing impurities: remove lumps or unqualified materials from the material by filtration, the precision can be more than 98%.

3. Filtration: Remove particles/foreign matter in liquid material, the filtration capacity is up to 5 tons per hour.

How it works:

The use of vertical vibration motor as the source of excitation, through the vibration motor up and down the two ends of the eccentric weight of the rotary motion into horizontal, vertical, tilted three-dimensional motion, and transfer to the rotary vibration sieve screen surface; materials through the feed port into the equipment, according to different material screening requirements, the material through the screen mesh sieve layer, in the process, is located in the screen mesh under the screen mesh clearing device - bouncing ball constantly impact on the screen mesh, so that the screen mesh In this process, the clearing device located under the screen mesh - bouncing ball constantly impacts the screen mesh, so that the upper layer of materials can be screened smoothly through the mesh, and effectively solve the problem of material clogging appears, the upper and lower materials are discharged from the different outlets, so as to realize the screening of impurities or filtration and grading purposes.

Product Features:

1. Adapt to a wide range of materials, can be screened to 500 mesh or 0.028mm powder, particles, liquid material filtration can be up to 5 microns;

2. Set up a bouncing ball mesh device, through constant impact on the screen to achieve the purpose of mesh clearing, no mesh blocking phenomenon, for viscous, electrostatic materials, in accordance with the ultrasonic mesh clearing device.

3. Fully closed structure, no dust overflow, improve the working environment;

4. It can screen 1 to 5 layers of screens, and can sort or filter 2 to 6 grades at the same time;

5. Impurities and coarse materials are discharged automatically, which can be operated continuously;

6. The discharge port can be rotated 360°, easy to operate.

Keyword:

Magnesium-based hydrogen storage materials

Cutting-edge ultrafine metal powder making equipment

Customized powder varieties can be customized for customers

Related Products

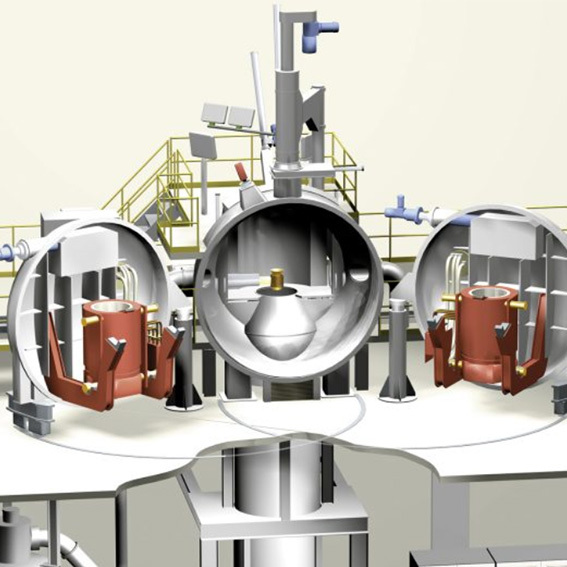

Vacuum melting gas atomization powder making experimental grade equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum melting gas atomization powder making equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum Suspension Melting Aerosolized Powder Making Experimental Grade Equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Vacuum suspension melting gas atomization powder making equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Just in touch us

Address

No.346 Ninghe Road, Yinzhou District, Ningbo City, Zhejiang Province

Tel

Technical consulting

86-13980131787(Mr.liu)

86-13736014811(Miss Liu)