Ningbo Lituo Superfine Materials Co., LTD.

Adopting vacuum atomisation process, the oxygen content is lower than 300ppm, the spherical powder with good sphericity can be used in metal 3D printing, injection moulding, powder metallurgy and repairing corrosion-resistant workpieces.

Main technical properties of stainless steel powder

| Chemical composition (%) | |||||||||||||

| Grades | Ni | Cr | Fe | Mo | P | S | Ti | Mn | Si | N | Ac/Ta | Cu | C |

| 304L | 8.0-12.0 | 18.0-20.0 | Bal | / | ≤0.045 | ≤0.03 | / | ≤2.0 | ≤0.75 | ≤0.1 | / | ≤0.03 | |

| 316L | 10.0-14.0 | 16.0-18.0 | Bal | 2.0-3.0 | ≤0.045 | ≤0.03 | / | ≤2.0 | ≤0.75 | ≤0.1 | / | ≤0.08 | |

| 316Ti | 10.0-14.0 | 16.0-18.0 | Bal | 2.0-3.0 | ≤0.045 | ≤0.03 | ≥5C%-0.7 | ≤2.0 | ≤0.75 | ≤0.1 | / | ≤0.08 | |

| 317L | 11.0-15.0 | 18.0-20.0 | Bal | 3.0-4.0 | ≤0.045 | ≤0.03 | / | ≤2.0 | ≤0.75 | ≤0.1 | / | ≤0.08 | |

| F321 | 9.0-12.0 | 17.0-19.0 | Bal | / | ≤0.035 | ≤0.03 | ≥5C% | ≤2.0 | ≤1.0 | / | / | ≤0.08 | |

| 310 | 19.0-22.0 | 24.0-26.0 | Bal | / | ≤0.045 | ≤0.03 | / | ≤2.0 | ≤1.5 | / | / | ≤0.25 | |

| 310S | 19.0-22.0 | 24.0-26.0 | Bal | / | ≤0.045 | ≤0.03 | / | ≤2.0 | ≤1.5 | / | / | ≤0.08 | |

| 310H | 19.0-22.0 | 24.0-26.0 | Bal | / | ≤0.045 | ≤0.03 | / | ≤2.0 | ≤0.75 | / | / | 0.04-0.1 | |

| 347 | 9.0-13.0 | 17.0-19.0 | Bal | / | ≤0.045 | ≤0.03 | / | ≤2.0 | ≤0.75 | / | 10*(C+N)-1.0 | ≤0.08 | |

| 347H | 9.0-13.0 | 17.0-19.0 | Bal | / | ≤0.045 | ≤0.03 | / | ≤2.0 | ≤0.75 | / | 8*(C+N)-1.0 | 0.04-0.1 | |

| 2205 | 4.5-6.5 | 22.5-23.0 | Bal | 3.2-3.5 | ≤0.03 | ≤0.15 | / | / | ≤1.0 | 0.14-0.2 | / | ≤0.03 | |

| 904L | 23.0-28.0 | 19.0-23.0 | Bal | 4.0-5.0 | ≤0.045 | ≤0.035 | / | ≤2.0 | ≤1.0 | / | / | 1.0-2.0 |

/ 、 |

Adopting true air atomisation process, we can get spherical powder with oxygen content lower than 300ppm, the particle size of the powder is uniform, with few satellite balls, which is mainly used in the fields of mould manufacturing and repairing, metal 3D printing, cutting tool industry and so on,

Main technical properties of industrial mould steel powder

Chemical composition (%):

| Grades | C | Si | Mn | Cr | Mo | V | Fe |

| H13 | 0.32-0.45 | 0.8-1.2 | 0.2-0.5 | 4.75-5.5 | 1.1-1.75 | 0.8-1.2 | Bal |

| T12 | 1.15-1.24 | ≤0.35 | ≤0.4 | Bal |

| Powder properties: | |||||

| Grades | Specification (um) | Specification (um) | Bulk density g/cm³ | Hall Flow Rate (s) | Oxygen content (ppm) |

| H13 | 15-53 | ball-shaped | ≥4.0 | ≤23 | ≤300 |

| 53-106 | ball-shaped | ≥4.1 | ≤20 | ≤300 | |

| T12 | 15-53 | ball-shaped | ≥4.0 | ≤23 | ≤300 |

| 53-106 | ball-shaped | ≥4.1 | ≤20 | ≤300 | |

Keyword:

Magnesium-based hydrogen storage materials

Cutting-edge ultrafine metal powder making equipment

Customized powder varieties can be customized for customers

Related Products

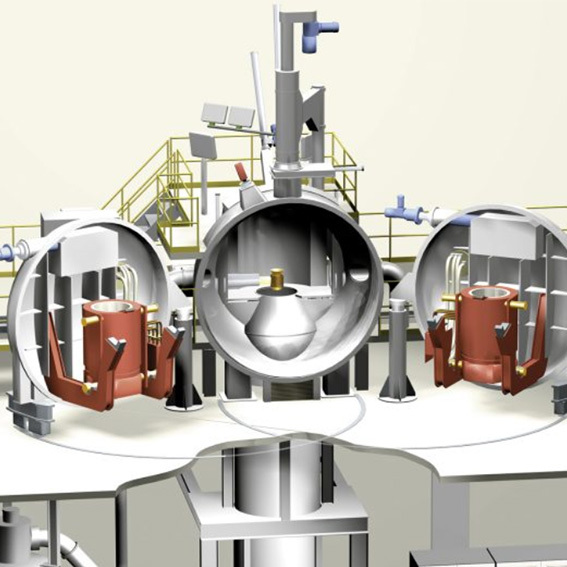

Vacuum melting gas atomization powder making experimental grade equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum melting gas atomization powder making equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum Suspension Melting Aerosolized Powder Making Experimental Grade Equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Vacuum suspension melting gas atomization powder making equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Just in touch us

Address

No.346 Ninghe Road, Yinzhou District, Ningbo City, Zhejiang Province

Tel

Technical consulting

86-13980131787(Mr.liu)

86-13736014811(Miss Liu)