Ningbo Lituo Superfine Materials Co., LTD.

Classification:

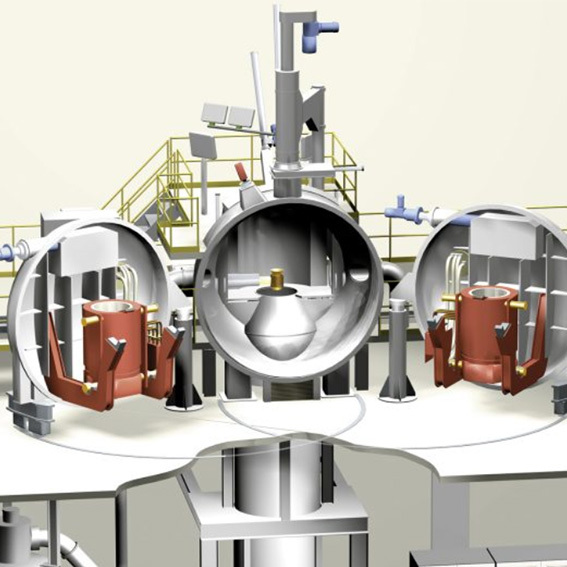

Plasma cladding equipment

Plasma cladding technology is a new type of material surface modification technology that uses plasma beam as heat source to make the surface layer of metal obtain excellent wear resistance, corrosion resistance, heat resistance, impact resistance and other properties. The technology is in the plasma high-energy beam irradiation, will be synchronised to the surface of the workpiece alloy powder melting, and make the surface of the workpiece surface at the same time the shallow layer melting, the formation of alloy melting pool on the surface of the workpiece; to be moved away from the high-energy beam, in the workpiece's own rapid heat conduction and the role of radiation heat transfer of the workpiece around the air, the alloy melting pool rapid solidification, so as to form the composition of uniformity, denseness, fine and uniform organisation, no micro pores and cracks, and the formation of good workpiece surface modification technology. It forms a high-quality coating with good metallurgical bonding with the workpiece, which has uniform composition, fine and uniform structure, no microscopic pores and cracks. Plasma cladding is a rapid non-equilibrium solidification process, with supersaturated solid-liquid reinforcement, diffusion reinforcement and precipitation reinforcement and other strengthening effects. Compared with laser cladding and electron beam cladding, plasma cladding is a kind of high quality, high efficiency and low cost surface modification technology.

INQUIRY

Equipment Description:

Plasma cladding technology is a new type of material surface modification technology that uses plasma beam as heat source to make the surface layer of metal obtain excellent wear resistance, corrosion resistance, heat resistance, impact resistance and other properties. The technology is in the plasma high-energy beam irradiation, will be synchronised to the surface of the workpiece alloy powder melting, and make the surface of the workpiece surface at the same time the shallow layer melting, the formation of alloy melting pool on the surface of the workpiece; to be moved away from the high-energy beam, in the workpiece's own rapid heat conduction and the role of radiation heat transfer of the workpiece around the air, the alloy melting pool rapid solidification, so as to form the composition of uniformity, denseness, fine and uniform organisation, no micro pores and cracks, and the formation of good workpiece surface modification technology. It forms a high-quality coating with good metallurgical bonding with the workpiece, which has uniform composition, fine and uniform structure, no microscopic pores and cracks. Plasma cladding is a rapid non-equilibrium solidification process, with supersaturated solid-liquid reinforcement, diffusion reinforcement and precipitation reinforcement and other strengthening effects. Compared with laser cladding and electron beam cladding, plasma cladding is a kind of high quality, high efficiency and low cost surface modification technology.

Keyword:

Magnesium-based hydrogen storage materials

Cutting-edge ultrafine metal powder making equipment

Customized powder varieties can be customized for customers

Related Products

Vacuum melting gas atomization powder making experimental grade equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum melting gas atomization powder making equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum Suspension Melting Aerosolized Powder Making Experimental Grade Equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Vacuum suspension melting gas atomization powder making equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Just in touch us

Address

No.346 Ninghe Road, Yinzhou District, Ningbo City, Zhejiang Province

Tel

Technical consulting

86-13980131787(Mr.liu)

86-13736014811(Miss Liu)