Ningbo Lituo Superfine Materials Co., LTD.

Classification:

Air flow ultra-micro pulverizer series equipment

The basic composition of the gas mill production line includes: gas compressor, gas tank, gas dryer, air purification filters, gas mill, cyclone separator, bag duster and induced draft fan and so on. One of the airflow mill by the spiral gas pedal, crushing chamber, grading room and other components, the use of low-temperature, high-pressure gas through a special device of supersonic nozzle generated by the high-speed airflow contains a huge kinetic energy, so that the material with the gas acceleration impact on each other to achieve the purpose of crushing.

INQUIRY

The basic composition of the gas mill production line includes: gas compressor, gas tank, gas dryer, air purification filters, gas mill, cyclone separator, bag duster and induced draft fan and so on. One of the airflow mill by the spiral gas pedal, crushing chamber, grading room and other components, the use of low-temperature, high-pressure gas through a special device of supersonic nozzle generated by the high-speed airflow contains a huge kinetic energy, so that the material with the gas acceleration impact on each other to achieve the purpose of crushing.

Air flow pulverizer medium gas is mainly air, inert gas and superheated steam, etc., the requirements of oil-free, dry, pressure of 0.8-1.2Mpa.

MK/CF series of airflow mill is a new generation of ultra-fine airflow milling equipment, set the international advanced multi-barrel technology, fluidized bed technology and horizontal classification technology in one, to achieve the flow field diversification, material layer fluidization, classification of horizontal and electromechanical integration of the combined technology system, is the direction of the development of the airflow mill. The ultra-fine powder made by this machine has the advantages of narrow particle size distribution, high uniformity, easy to control the shape of particles, good dispersion, no wear and tear pollution of the research body, etc. It can be widely used in the pharmaceutical, chemical, metallurgical, mining, energy, electronics, medicine, pesticides, plastics, papermaking, pigment coatings, dyes, abrasive materials, food, cosmetics, etc., and can also be used for the preparation of some special materials. Such as: polymer materials, advanced electromagnetic materials, magnetic materials, semiconductor materials, fine chemical powder materials, catalysts, reagents and chemicals, propellants and other high-purity powder products.

Performance Characteristics:1. Low energy consumption, compared with other types of air flow pulverizer energy saving 30-40%, the output should be increased by 1/3.

2. Compressed air through the freeze dryer out of the gas is always kept in the set low temperature range, the nozzle mouth temperature of -50 ℃ ~ -165 ℃, so especially suitable for heat-sensitive and viscous materials crushed.

3. Suitable for dry ultra-micro process, the airflow impact speed of up to 1-3.08 Mach, the device uses a closed-circuit crushing device, the material and the crushing chamber wall does not produce friction, so as to ensure the purity of the crushed material, no pollution.

4. The equipment set crushing, grading in one, compact structure, low noise, no vibration. Can be continuously crushed, high efficiency. Easy to disassemble and clean.

5. All the equipment operation realizes human-machine interface and PLC automatic control, which improves the production efficiency.

For flammable, explosive materials can be used inert gas as a work material for crushing.

Keyword:

Magnesium-based hydrogen storage materials

Cutting-edge ultrafine metal powder making equipment

Customized powder varieties can be customized for customers

Related Products

Vacuum melting gas atomization powder making experimental grade equipment

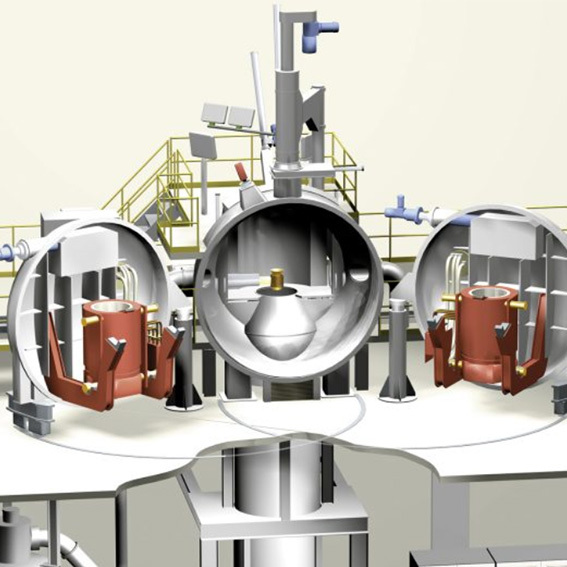

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum melting gas atomization powder making equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum Suspension Melting Aerosolized Powder Making Experimental Grade Equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Vacuum suspension melting gas atomization powder making equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Just in touch us

Address

No.346 Ninghe Road, Yinzhou District, Ningbo City, Zhejiang Province

Tel

Technical consulting

86-13980131787(Mr.liu)

86-13736014811(Miss Liu)