Ningbo Lituo Superfine Materials Co., LTD.

Classification:

Powder Making Equipment Supporting Facilities-Classifier

After the material is put into the main machine through the feeding system, it is classified according to the principle that particles of different sizes are subjected to different sizes of centrifugal force in the vortex field.

INQUIRY

I. Introduction to the principle

After the material is put into the main machine through the feeding system, it is graded according to the principle that particles of different sizes are subjected to different sizes of centrifugal force in the vortex field. The gas enters into the classifier through the primary air inlet, and the materials to be graded enter into the upper box of the classifier from the inlet, and both of them are dispersed and evened out by the rotating airflow field produced by the high-speed rotating grading wheel, and fall into the area of the deflector disc, and converge with the deflected airflow to get the mixed and uniform gas and material flow.

Mixed gas and material flow along the edge of the grading wheel into the grading wheel, spiral to the centre of the grading wheel movement, fine particles with the inert gas through the gap in the grading wheel into the powder pipeline, the fine powder from the lead cylinder discharged to the cyclone separator, the pulse of the bag collector for collection; relatively coarse particles due to the centrifugal force is greater than that produced by the airflow viscous resistance is thrown out of the grading wheel, by one or two winds The relatively coarse particles are thrown out of the grading wheel due to the centrifugal force is greater than the viscous resistance of the air flow, and then collected by the outlet of the coarse powder after cleaning by the first and second wind.

2、The performance and advantages of the product

1、Precise grading limit and cutting vertex, Newtonian grading efficiency η: 60~95%.

2、Flammable, explosive and oxidising metal powder can be classified by inert gas as medium to achieve closed-circuit classification, inert gas can be recycled, low energy consumption.

3、Horizontal high-speed small diameter grading turbine strictly control large particles.

4、Remove too fine or too coarse particles in the material, effectively solve the phenomenon of entrainment, especially the fine powder extraction is more thorough and stable.

5, the machine can also be used with a variety of crushing equipment (such as: air mill, ball mill, Raymond mill, vibration mill, etc.) combined with a fine powder.

6, the system always maintains stable operation, no need to readjust the operating parameters each time the machine is switched on.

Keyword:

Magnesium-based hydrogen storage materials

Cutting-edge ultrafine metal powder making equipment

Customized powder varieties can be customized for customers

Related Products

Vacuum melting gas atomization powder making experimental grade equipment

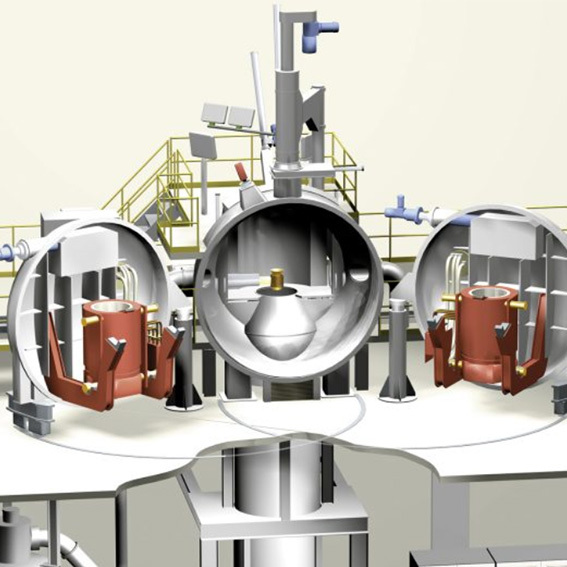

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum melting gas atomization powder making equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum Suspension Melting Aerosolized Powder Making Experimental Grade Equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Vacuum suspension melting gas atomization powder making equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Just in touch us

Address

No.346 Ninghe Road, Yinzhou District, Ningbo City, Zhejiang Province

Tel

Technical consulting

86-13980131787(Mr.liu)

86-13736014811(Miss Liu)