Ningbo Lituo Superfine Materials Co., LTD.

Classification:

Pneumatic Mixer

When the air stored under pressure at the bottom of the mixer is instantly sprayed, the powder and granular body in the can becomes boiling and begins to mix and blend fully. The injected air is discharged by the air filter above. With a very short injection time and very little compressed air consumption, it is possible to fully mix and homogenize efficiently.

INQUIRY

Principle of operation.

When the air stored under pressure at the bottom of the mixer is instantly sprayed, the powder and granular body in the can becomes boiling and begins to mix and blend fully. The injected air is discharged by the air filter above. With a very short injection time and little compressed air consumption, it is possible to fully mix and homogenize efficiently. Combined with raw material transportation, the introduction of touch screen and PLC control makes it easy to set up an automatic raw material handling production line.

Features of the pneumatic mixer:

1. Fast mixing large capacity batch of materials mixed evenly in just a few minutes, a mix from a few tons to dozens of tons, saving mixing operating costs.

2. No dead-end design, no recessed round holes, corner residue, etc..

3. No mechanical rotating parts in the mixer so there is no friction to generate heat, and there is no lubricant to contaminate the product. Because there is no churning, it can be mixed without damage, such as chicken essence, compound fertilizer particles, etc.. Especially suitable for mixing micro-powder, will not jam the rotating machinery, such as bearings, etc., trouble-free for a long time.

4. Closed mixing, no dust pollution.

5. Intelligent, automated, one key operation unmanned operation.

6. Low energy consumption, low cost, unit energy consumption is only 30-60% of mechanical mixing.

Technical parameters:

Compressed air operating pressure (Mpa): 0.8 ~ 1.5

Mixing time (min): 3~5

Loading factor: 0.4~0.6

Operating temperature (℃): atmospheric pressure

Working pressure inside the cylinder (Mpa): micro-negative pressure

Keyword:

Magnesium-based hydrogen storage materials

Cutting-edge ultrafine metal powder making equipment

Customized powder varieties can be customized for customers

Related Products

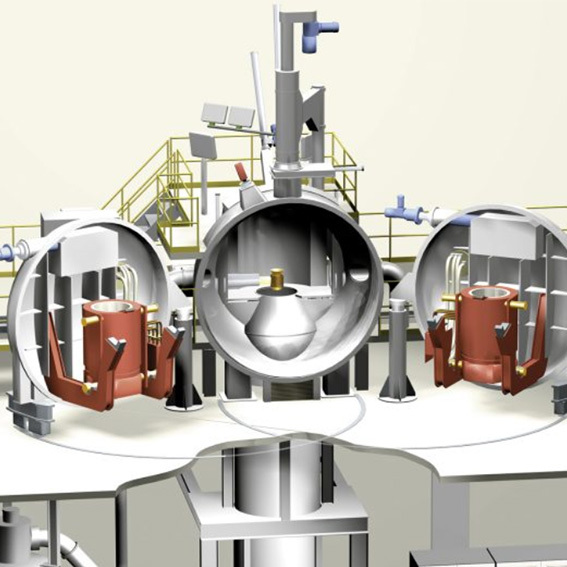

Vacuum melting gas atomization powder making experimental grade equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum melting gas atomization powder making equipment

Vacuum melting gas atomization powder making equipment is a modern powder making equipment that melts metal materials under vacuum condition (or inert gas filling) by using the principle of mid-frequency induction, and the molten liquid is atomized by pouring to the guide nozzle in the lower part of the intermediate package for high ultrasonic gas atomization and rapid solidification.

Vacuum Suspension Melting Aerosolized Powder Making Experimental Grade Equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Vacuum suspension melting gas atomization powder making equipment

Vacuum suspension melting gas atomization powder making equipment uses medium frequency induction heating principle to melt the metal material under vacuum condition (or inert gas filling), and at the same time, it pushes the metal liquid away from the water-cooled copper crucible by using magnetic squeezing and stirring, which is in suspended state and avoids contamination of the crucible to the metal liquid.

Just in touch us

Address

No.346 Ninghe Road, Yinzhou District, Ningbo City, Zhejiang Province

Tel

Technical consulting

86-13980131787(Mr.liu)

86-13736014811(Miss Liu)