Ningbo Lituo Superfine Materials Co., LTD.

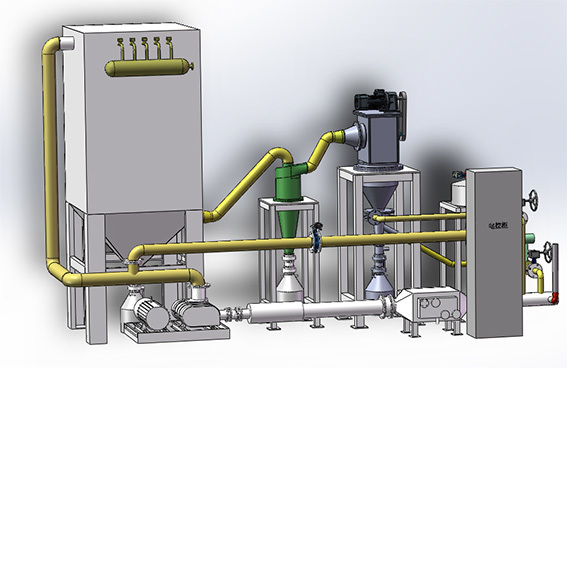

Cutting-edge ultrafine metal powder making equipment

Double power mixer is a new type, high efficiency, fine container rotary blade mixer, with a variety of powdered, granular materials mixed evenly, with a high degree of uniformity of mixing, the specific gravity of the difference between large, small amount of ingredients can also achieve a better mixing degree.

When the air stored under pressure at the bottom of the mixer is instantly sprayed, the powder and granular body in the can becomes boiling and begins to mix and blend fully. The injected air is discharged by the air filter above. With a very short injection time and very little compressed air consumption, it is possible to fully mix and homogenize efficiently.

Powder Making Equipment Supporting Facilities-Classifier

After the material is put into the main machine through the feeding system, it is classified according to the principle that particles of different sizes are subjected to different sizes of centrifugal force in the vortex field.

Plasma cladding technology is a new type of material surface modification technology that uses plasma beam as heat source to make the surface layer of metal obtain excellent wear resistance, corrosion resistance, heat resistance, impact resistance and other properties. The technology is in the plasma high-energy beam irradiation, will be synchronised to the surface of the workpiece alloy powder melting, and make the surface of the workpiece surface at the same time the shallow layer melting, the formation of alloy melting pool on the surface of the workpiece; to be moved away from the high-energy beam, in the workpiece's own rapid heat conduction and the role of radiation heat transfer of the workpiece around the air, the alloy melting pool rapid solidification, so as to form the composition of uniformity, denseness, fine and uniform organisation, no micro pores and cracks, and the formation of good workpiece surface modification technology. It forms a high-quality coating with good metallurgical bonding with the workpiece, which has uniform composition, fine and uniform structure, no microscopic pores and cracks. Plasma cladding is a rapid non-equilibrium solidification process, with supersaturated solid-liquid reinforcement, diffusion reinforcement and precipitation reinforcement and other strengthening effects. Compared with laser cladding and electron beam cladding, plasma cladding is a kind of high quality, high efficiency and low cost surface modification technology.

Laser Intelligent Composite Processing Centre

High-speed laser cladding is an advanced metal surface treatment technology, the use of high energy density of the laser beam so that the alloy powder material and high speed movement of the surface of the substrate material at the same time melting, and rapid solidification to form an alloy cladding coatings, which is characterised by a very low dilution rate, and the substrate is a metallurgical combination, cladding efficiency, is to improve the surface of the mechanical parts of the surface of the wear-resistant, corrosion-resistant, heat-resistant, oxidation-resistant and other characteristics of the process of the new process of advanced technology. It is a new advanced technology to improve the surface wear resistance, corrosion resistance, heat resistance and oxidation resistance of mechanical parts.